All competencies under one single supplier.

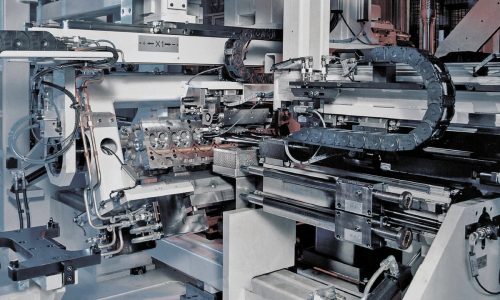

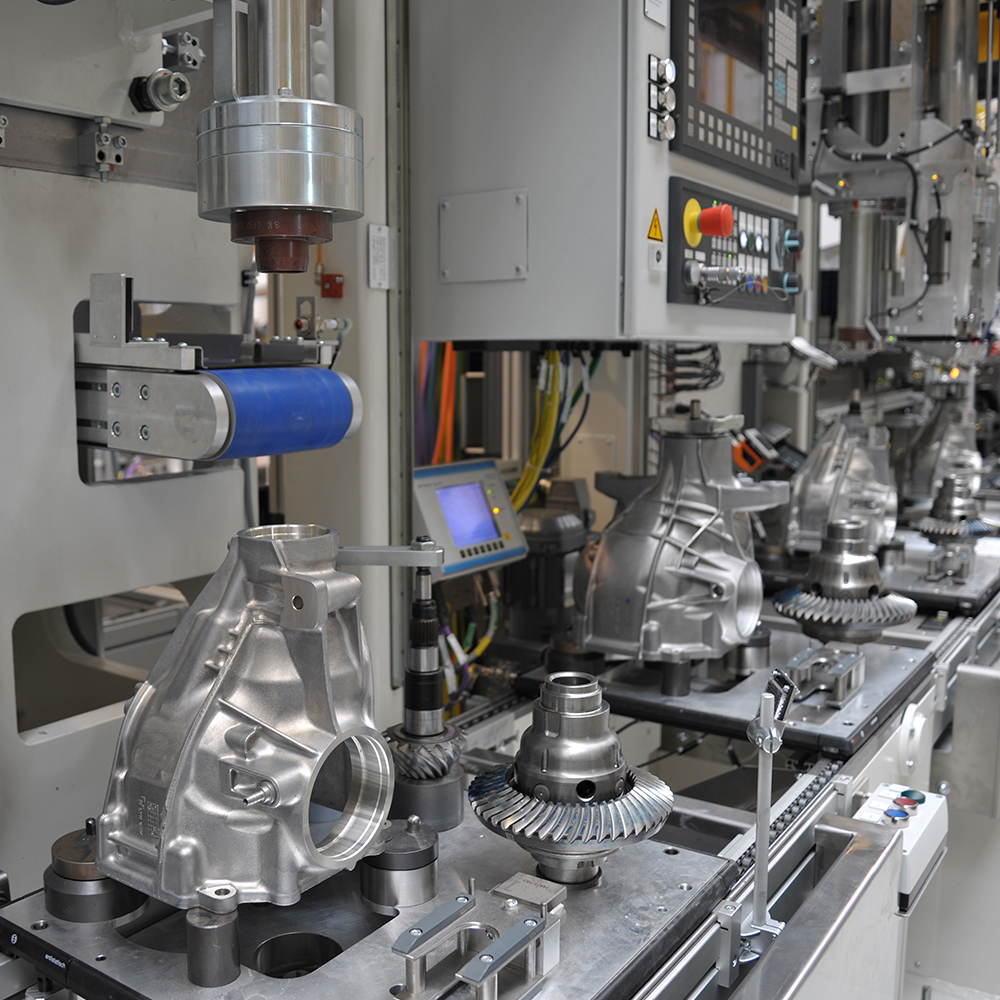

Years of experience in the conceptual design of assembly systems make INTELMAN a competent and reliable expert in the assembly technology industry. All assembly stations and assembly lines are modular and custom-built to meet the specific needs of our customers. A tried and tested assembly concept allows us to make flexible modifications to our systems to adapt to various tasks, resulting in sophisticated and precise production. The INTELMAN assembly concept is suitable for both fully automated lines and partially automated solutions with manual assembly stations.

Fully automated systems can help increase production volumes without increasing labor, especially when your product will be manufactured in the long term.

APPLIED TECHNOLOGIES AND PROCESSES

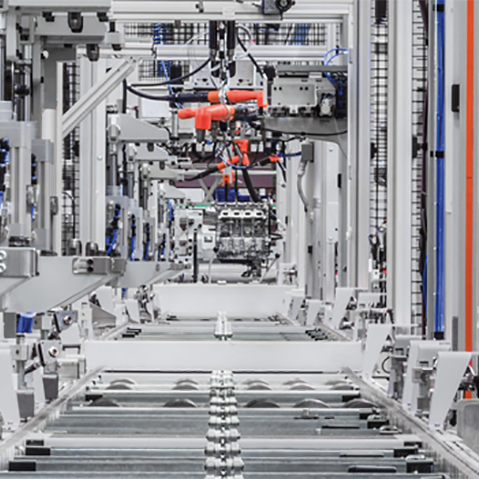

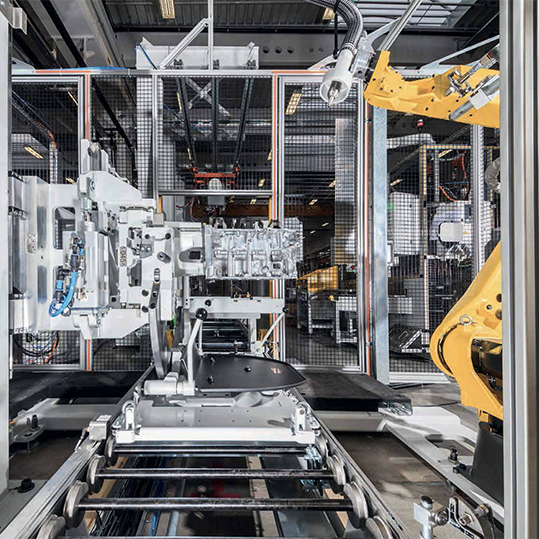

In-depth knowledge and the use of the latest technologies make INTELMAN a recognized expert in the systems business. To precisely meet the requirements of its customers, INTELMAN produces complete system solutions in the form of high-quality, customizable manufacturing lines. These lines mainly consist of modular stations and special machines that are interconnected with the latest automation solutions.

From planning to engineering, through delivery and operationally ready commissioning, INTELMAN offers all the core competencies from a single supplier. This deep vertical integration allows for dynamic and customer-specific adjustments to capabilities and ensures an excellent degree of reliability.

AUTOMATIC SCREW DRIVING

Volumetric or proportional dispensers, with servo drive and control.

INSERTION AND PRESSING

Integrable in line or dedicated stations, which can be fed manually or automatically.

AUTOMATIC DOSING

Volumetric or proportional dispensers, with servo drive and control, allow the application of a wide variety of materials.

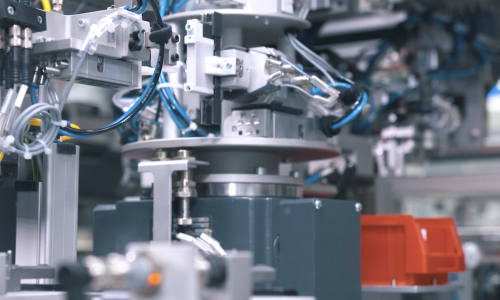

ROBOTICS AND HANDLING

Automated handling and industrial robots for assembly and handling processes.

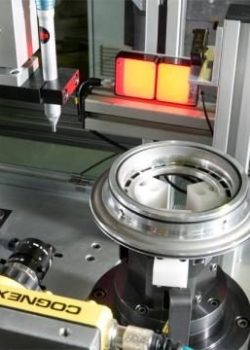

TRACEABILITY AND MARKING

In-line marking and identification for recording process and component traceability.

RESISTANCE WELDING

Resistance welding is a thermoelectric process for joining metals where heat is generated by passing an electric current through the parts, which are joined under controlled pressure.

LEAK TEST

Leak tests control are crucial for quality control test. Different process such as pressure drop, vacuum drop, mass flow and flow control, tracer gas (helium mass spectrometer),

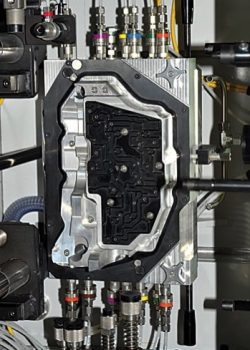

TEST AND CONTROL

Today's products require versatile testing systems capable of running advanced test cycles,, electrical testing equipment, and other advanced control capabilities.

SMED

Quick-change manual or automatic systems to minimize changeover times. Precision mechanical coupling and integrated power, signal, and communication transmission.

IN-LINE WEIGHING

Weighing scales and industrial scales can be used for simple weighing, legal-for-trade weighing, counting, mixing, filling and dosing, and many other processes.