Dynamic markets require flexible investments.

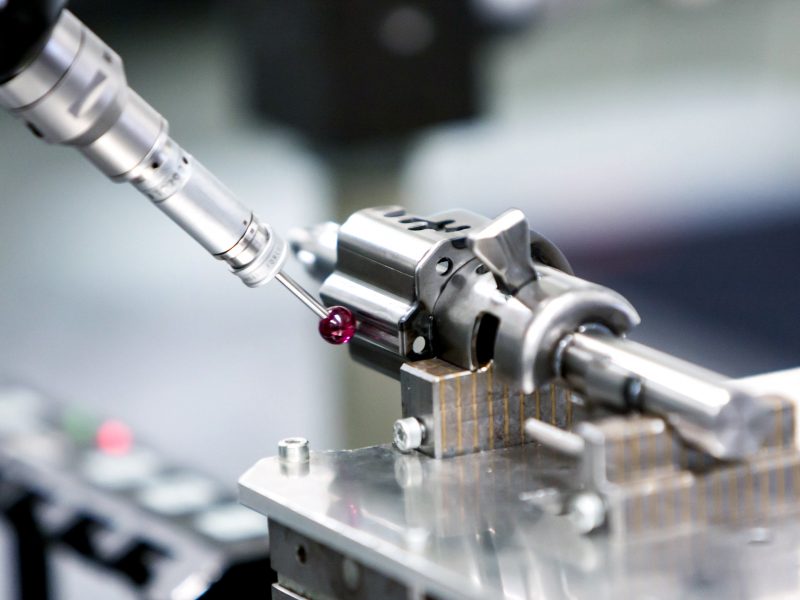

INTELMAN in the industry

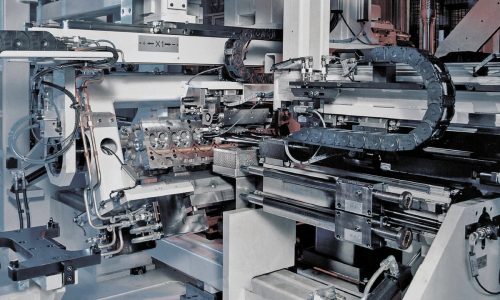

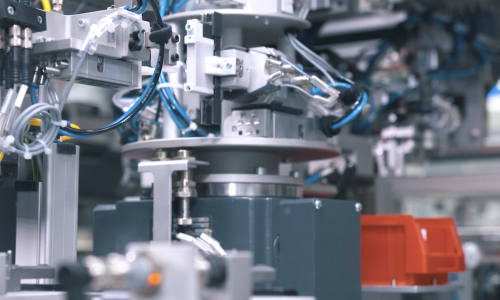

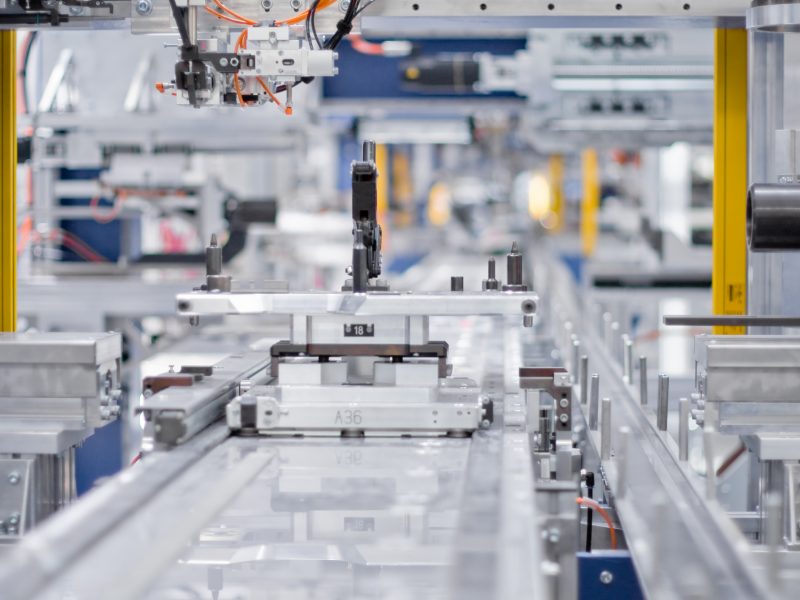

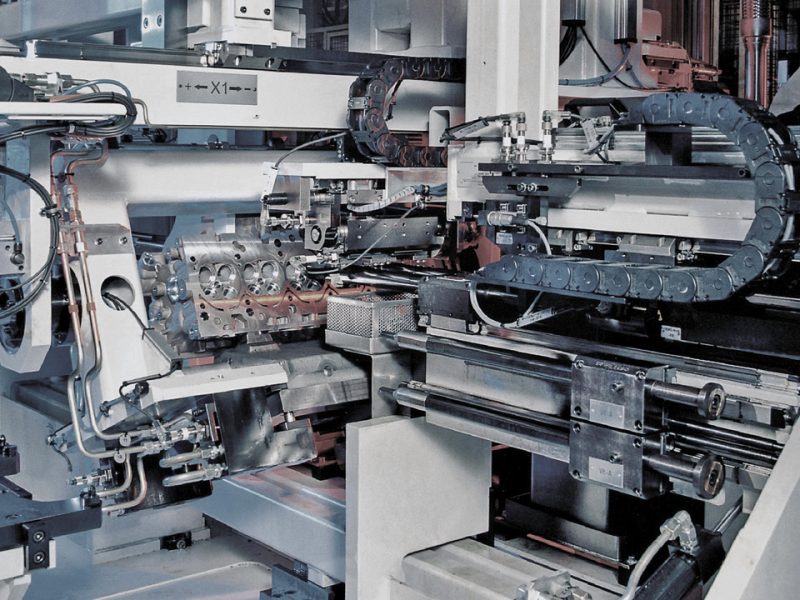

INTELMAN offers comprehensive automation solutions, including material feeding, logistics and packaging systems, assembly and process modules, and transport systems.

Depending on the characteristics and functionalities required, our machines are easily expandable, which guarantees a fast start-up production. Your production responds in real time and is a short step from the product idea to series production.

Whether you use modules not linked to processes or manual work, flexible assembly cells and loose or interconnected high-performance machines: we update your production automation with respect to individual requirements.

A constant development oriented to the improvement and optimization of our solutions, a unique benefit for our clients.

A constant development oriented to the improvement and optimization of our solutions, a unique benefit for our clients.

A constant development oriented to the improvement and optimization of our solutions, a unique benefit for our clients.

We adapt the processes to meet your needs

Our process is customer-centered, not based on a task checklist, but on your satisfaction. You set the direction; We work in each phase as often as necessary to meet your needs. Our technical creativity allows us to design your solution while finalizing your specifications. Each step of our process is designed to mitigate your risk and eliminate surprises.

ANALYSIS AND CONCEPTUAL EVALUATION

We start by examining your business objectives, the overall manufacturing process, the plant environment, operator capabilities, industry regulations, and end-user expectations. We then apply our years of experience to identify and address all of your challenges to obtain the best and most cost-effective solution.

COST ANALYSIS

With a concept in mind, we begin to align potential solutions to your budget. We can review the cost analysis several times throughout your project as you complete the design of your device and as your team takes shape. Above all, our goal is to design the right equipment solution.

DESIGN

We represent the application in the form of a model and present the design intent to ensure that the program fits your vision. Our engineers evaluate the design for risks, safety and ergonomics, and product and process controls. As you provide feedback, we continually refine our solution to keep up with your functional needs and budgetary expectations.

MANUFACTURING

We manufacture parts and source components, assemble and integrate your equipment, and debug the mechanics and programming. As you refine the design of your device and conduct engineering studies, we review the equipment to be in sync with your requirements.

INSTALLATION AND SERVICE

Acceptance runs confirm that the equipment is working as intended, and production workers are invited to test the equipment and receive training on interfaces, preventive maintenance, and configuration. The result: you ensure that your equipment works as intended and gain stakeholder buy-in before installing your equipment.

Everything in one supplier to help you get to market faster